Colorado Springs Fine Arts Center at Colorado College

The Colorado Springs Fine Arts Center at Colorado College in Colorado Springs, Colorado has a large collection of Rio Grande textiles. With hopes of viewing some of these, I contacted Polly Nordstrand, their Curator of Southwest Art. I met with her and Michael Lorusso, Assistant Registrar regarding various aspects of collections management. We began with a review of their accessioning process, the TMS (The Museum System) relational database software, and cataloging procedure. We discussed research methods and interpretive labels for exhibits, for which they tend to use inquiry-based label writing, where a question is posed in the label text that is answered in the exhibit objects.

We viewed several of the large basement storage rooms that house pottery, paintings, sculptures, furniture, and textiles. Pottery sits in pot rings, made of flexible foam cylinders, hot-glued end-to-end. Larger pots with unstable bottoms sit in soft sand bag “snakes” so they will not tip over. Paintings are hung on rolling racks that look somewhat like sections of giant chain-link fence. Some of the sculptures are housed in cabinets, with larger pieces above. For pest management, they use sticky traps and new acquisitions are isolated for a period of time, sealed in plastic.

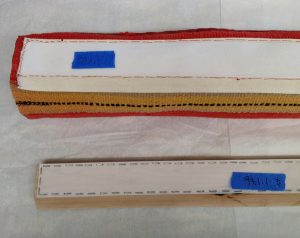

Textiles are stored in tall racks with pullout “trays” that hold a number of horizontal rods. Each rod holds a tube wrapped in archival paper. The textiles are rolled around the tube with archival tissue paper, to prevent transfer of grime or dye within the textile, and also to provide some padding. The rolled textiles loosely tied with cotton muslin, then wrapped in plastic sleeves, and the ends of the plastic are tied with cotton twill tape. The textile accession number is printed on a small piece of cotton muslin that is sewn onto the textile. A label, including a photograph, accession number, and object information, is affixed to the plastic sleeve. Although we did not pull textiles from storage, I did view a beautiful Rio Grande textile on exhibit, as well as the interpretive labels for the exhibit.

My project was selected and my presentation was titled “Rio Grande Blankets: An Exhibition Process”.

My project was selected and my presentation was titled “Rio Grande Blankets: An Exhibition Process”.

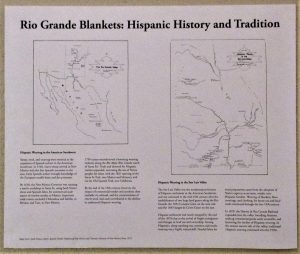

The first map shows the Rio Grande Valley including Colorado, New Mexico, and Mexico, and shows early trade routes. The accompanying text: Hispanic Weaving in the American Southwest describes the rise and trading of Rio Grande blankets. The second map shows the San Luis Valley, Colorado and the two land grants that lead to settlement in this valley, bounded and separated by the Rio Grande: the Conejos Grant on the east and the Sangre de Cristo Grant on the west. The accompanying text: Hispanic Weaving in the San Luis Valley, Colorado discusses settlement of the valley, the rise of sheep ranching among Hispanic settlers, and the arrival of railroads with commercial goods that contributed to the decline in traditional Hispanic weaving. With the installation of this poster at the entry point, the exhibit was complete.

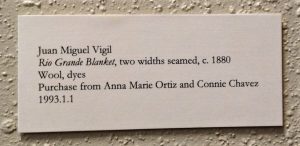

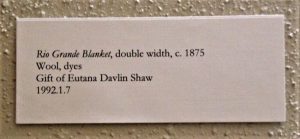

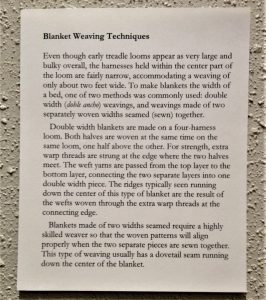

The first map shows the Rio Grande Valley including Colorado, New Mexico, and Mexico, and shows early trade routes. The accompanying text: Hispanic Weaving in the American Southwest describes the rise and trading of Rio Grande blankets. The second map shows the San Luis Valley, Colorado and the two land grants that lead to settlement in this valley, bounded and separated by the Rio Grande: the Conejos Grant on the east and the Sangre de Cristo Grant on the west. The accompanying text: Hispanic Weaving in the San Luis Valley, Colorado discusses settlement of the valley, the rise of sheep ranching among Hispanic settlers, and the arrival of railroads with commercial goods that contributed to the decline in traditional Hispanic weaving. With the installation of this poster at the entry point, the exhibit was complete. Interpretive labels provide visitors with information and the context: political, economic, societal, historical, and/or cultural, from which to view and better understand an exhibit. Accordingly, I developed a number of interpretive labels regarding key areas of interest, identified during my research into Rio Grande textiles. Blanket Weaving Techniques describes the two methods used to weave these textiles: double width and two widths seamed, both of which are represented in the displayed blankets.

Interpretive labels provide visitors with information and the context: political, economic, societal, historical, and/or cultural, from which to view and better understand an exhibit. Accordingly, I developed a number of interpretive labels regarding key areas of interest, identified during my research into Rio Grande textiles. Blanket Weaving Techniques describes the two methods used to weave these textiles: double width and two widths seamed, both of which are represented in the displayed blankets. Dyes: Natural and Synthetic discusses the dyestuffs used to create the wide palette of dyed wool colors used to weave the blankets and the historical discovery and introduction of synthetic dyes.

Dyes: Natural and Synthetic discusses the dyestuffs used to create the wide palette of dyed wool colors used to weave the blankets and the historical discovery and introduction of synthetic dyes.

WPA Weaving Revival discusses the 1930s Works Progress Administration project in San Luis, Colorado at which the weaver of one of the displayed blankets learned his craft.

WPA Weaving Revival discusses the 1930s Works Progress Administration project in San Luis, Colorado at which the weaver of one of the displayed blankets learned his craft.